Smartscan Safety Light Curtain 8K3 Series: Principle of Operation

Principle of Operation

The Smartscan sensing unit consists of a transmitter and a receiver column that face each other across an area to be safeguarded. The transmitter contains a row of infrared, light emitting diodes that sequentially transmit parallel beams of energy to corresponding receiving diodes in the receiver column. When the control/monitoring unit detects an obstruction in the optical path of one, or more of the beams that form the sensing field, the output signal switching devices (OSSD’s) will turn-OFF immediately.

Diagnostic Indicators

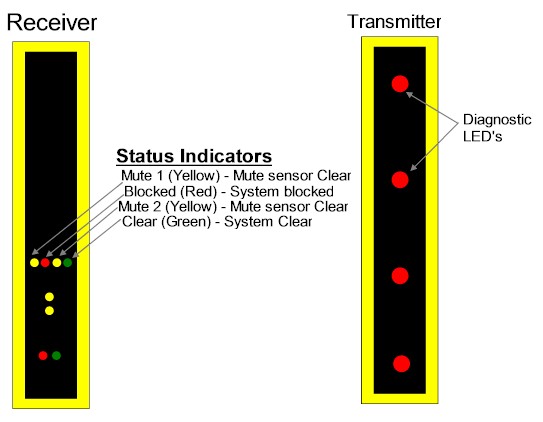

For diagnostic purposes visible red LED indicators adjacent to each infrared transmitting diode are provided, in the transmitter column.

The Smartscan sensing unit consists of a transmitter and a receiver column that face each other across an area to be safeguarded. The transmitter contains a row of infrared, light emitting diodes that sequentially transmit parallel beams of energy to corresponding receiving diodes in the receiver column. When the control/monitoring unit detects an obstruction in the optical path of one, or more of the beams that form the sensing field, the output signal switching devices (OSSD’s) will turn-OFF immediately.

Diagnostic Indicators

For diagnostic purposes visible red LED indicators adjacent to each infrared transmitting diode are provided, in the transmitter column.

Status Indicators

The physical location of these indicators can be viewed above.

Guard ‘clear’ indicator - A green LED indicator located in the top cluster of the receiver unit illuminates when the light curtain is clear of obstruction.

Guard 'blocked' indicator - A red LED indicator located in the top cluster of the receiver unit illuminates when the light curtain is blocked.

Mute ‘clear’ indicators M1 and M2- Yellow LED indicators located in the top cluster of the receiver unit extinguish when mute sensors M1 and M2 are blocked

Mute condition ‘on’ indicator- Yellow LED indicator located in the center cluster of the receiver

unit illuminates when the light curtain output relays are in a muted condition.

Status output indicator– An Yellow LED indicator located in the center cluster of the receiver unit

is illuminated when the status relay is de-energized, but extinguishes when the status relay

energizes.

Safe output ‘on'- A green LED indicator located in the bottom cluster of the receiver unit illuminates when the safe output switching relays are ON (Closed).

Safe output ‘off’ - A red LED indicator mounted located in the bottom cluster of the receiver unit illuminates when the safe output switching relays are OFF (Open).

The physical location of these indicators can be viewed above.

Guard ‘clear’ indicator - A green LED indicator located in the top cluster of the receiver unit illuminates when the light curtain is clear of obstruction.

Guard 'blocked' indicator - A red LED indicator located in the top cluster of the receiver unit illuminates when the light curtain is blocked.

Mute ‘clear’ indicators M1 and M2- Yellow LED indicators located in the top cluster of the receiver unit extinguish when mute sensors M1 and M2 are blocked

Mute condition ‘on’ indicator- Yellow LED indicator located in the center cluster of the receiver

unit illuminates when the light curtain output relays are in a muted condition.

Status output indicator– An Yellow LED indicator located in the center cluster of the receiver unit

is illuminated when the status relay is de-energized, but extinguishes when the status relay

energizes.

Safe output ‘on'- A green LED indicator located in the bottom cluster of the receiver unit illuminates when the safe output switching relays are ON (Closed).

Safe output ‘off’ - A red LED indicator mounted located in the bottom cluster of the receiver unit illuminates when the safe output switching relays are OFF (Open).

Modes Of Operation

Automatic Restart: After initial “Power Up” the light curtains OSSD’s become active (OSSD’s are “ON”). If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the light curtain automatically reactivates itself.

(OSSD’s turn “ON” )

Latched mode: After initial “Power Up” the light curtains OSSD’s become remain “OFF” until a start signal is received. Once a Start signal is received the OSSD’s turn “ON”. If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the OSSD’s will remain “OFF” until a Start signal is received, upon which time the OSSD’s will turn “ON”.

MUTE: In the muted mode the light curtains switching devices (OSSD’s) do not respond to actuation of the sensing unit. In other words, the light curtain does not send a shut down signal when one or more of the infrared beams are obstructed.

Automatic Restart: After initial “Power Up” the light curtains OSSD’s become active (OSSD’s are “ON”). If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the light curtain automatically reactivates itself.

(OSSD’s turn “ON” )

Latched mode: After initial “Power Up” the light curtains OSSD’s become remain “OFF” until a start signal is received. Once a Start signal is received the OSSD’s turn “ON”. If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the OSSD’s will remain “OFF” until a Start signal is received, upon which time the OSSD’s will turn “ON”.

MUTE: In the muted mode the light curtains switching devices (OSSD’s) do not respond to actuation of the sensing unit. In other words, the light curtain does not send a shut down signal when one or more of the infrared beams are obstructed.

Additional Functions

Guard Override Function: This function is a temporary suspension of the safety outputs (OSSD’s), following a tripped condition, during the period when the light curtain is obstructed. The suspension is limited to 3 minutes Once 3 minutes is surpassed, the signal has to be removed and then reapplied to get another 3 minutes. Once the obstruction is cleared the OSSD’s “OPEN”, and the system is ready to be reset. This signal must be held in the 'closed' position for the entire time

period.

Mute enable (Global Mute Enable) This signal adds an additional level of safety to the muting

circuit. Muting is not allowed unless this signal is applied.

Monitoring (EDM):External Device Monitoring (EDM)) is a means of detecting faults in equipment external to the light curtain that is involved in achieving the machine stop condition. For instance,

if external relays are used it may be necessary to ensure the relays respond each time the light

curtain is interrupted.

Guard Override Function: This function is a temporary suspension of the safety outputs (OSSD’s), following a tripped condition, during the period when the light curtain is obstructed. The suspension is limited to 3 minutes Once 3 minutes is surpassed, the signal has to be removed and then reapplied to get another 3 minutes. Once the obstruction is cleared the OSSD’s “OPEN”, and the system is ready to be reset. This signal must be held in the 'closed' position for the entire time

period.

Mute enable (Global Mute Enable) This signal adds an additional level of safety to the muting

circuit. Muting is not allowed unless this signal is applied.

Monitoring (EDM):External Device Monitoring (EDM)) is a means of detecting faults in equipment external to the light curtain that is involved in achieving the machine stop condition. For instance,

if external relays are used it may be necessary to ensure the relays respond each time the light

curtain is interrupted.