Smartscan Safety Light Curtain SG: Dipswitch (Direct) Settings

Direct Settings

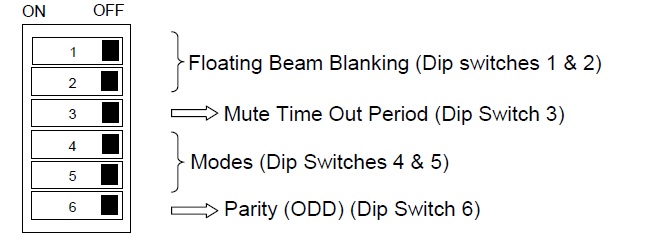

Direct settings are the functions that are available “out of the box”. No steps are needed to reach these functions. Place the dipswitches is the desired position then the desired functions are applied There are (4) four features available in the Direct Settings mode:

Direct settings are the functions that are available “out of the box”. No steps are needed to reach these functions. Place the dipswitches is the desired position then the desired functions are applied There are (4) four features available in the Direct Settings mode:

- Floating blanking

- Mute Dwell time

- Reset Modes

- Parity

Floating beam blanking

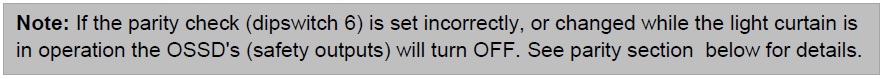

Floating beam blanking allows the user to create a larger unprotected opening in the light curtain safe guarding barrier. The name floating beam blanking originated due to the fact that the disabled beams are not fixed at a specific location. The light curtain will allow a specified number of beams (Maximum of 3 adjacent beams) to be blocked without it sending a stop signal to the safe guarded machine. Floating blanking allows the operator to manipulate the work piece safely without shutting down the machine. There are four options:

Floating beam blanking allows the user to create a larger unprotected opening in the light curtain safe guarding barrier. The name floating beam blanking originated due to the fact that the disabled beams are not fixed at a specific location. The light curtain will allow a specified number of beams (Maximum of 3 adjacent beams) to be blocked without it sending a stop signal to the safe guarded machine. Floating blanking allows the operator to manipulate the work piece safely without shutting down the machine. There are four options:

- Off

- 1 beam

- 2 adjacent beams

- 3 adjacent beams

Mute Dwell Time

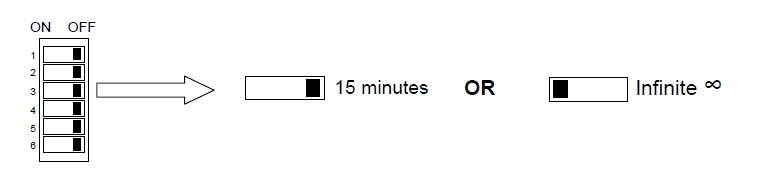

Mute dwell is the amount of time that the light curtain can remain in the muted state. There are two options:

Mute dwell is the amount of time that the light curtain can remain in the muted state. There are two options:

- 15 minutes

- Infinite

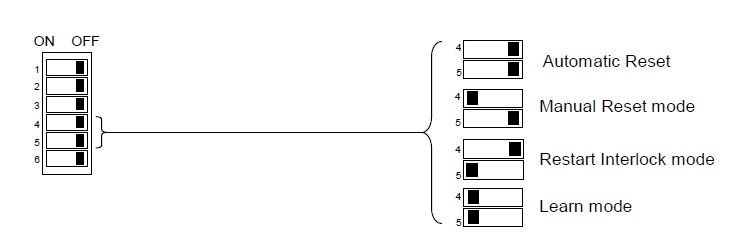

Modes of Operation

- Automatic Reset: After initial “Power Up” the light curtain OSSD’s become active (OSSD’s are “ON”). If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the light curtain automatically reactivates itself. (OSSD’s turn “ON”).

- Manual reset (Latched): After initial “Power Up” the light curtains OSSD’s remain “OFF” until a Reset signal is received. Once the reset signal is received the OSSD’s turn “ON”. If tripped, once the obstruction has been removed from the sensing unit the OSSD’s will remain “OFF” until a reset signal is applied, upon which time the OSSDs will turn “ON”.

- Restart Interlock: After initial “Power Up” the light curtains OSSD’s become active (OSSD’s turn “ON”). If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the OSSD’s will remain “OFF” until a reset signal is applied.

- Learned mode: Is the mode that allows the user to access additional features of the light curtains. These features include, fixed beam blanking, partial muting. Mute disparity and others.

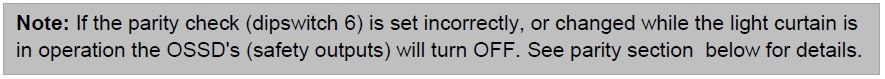

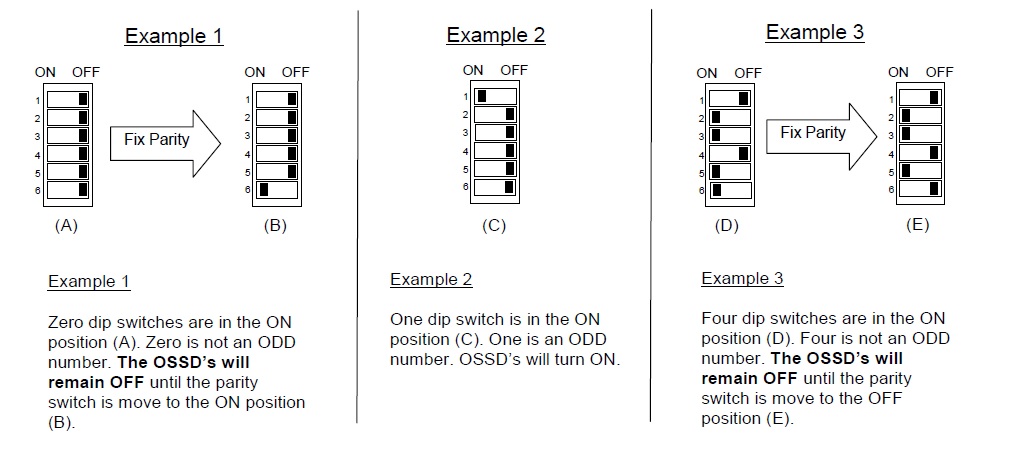

Parity (ODD)

The parity switch (Position 6) is used as a functionality check for the dip switches, making sure no dipswitch has failed. The light curtain counts how many of the 6 switches are in the ON position. This sum must be an odd number. If the number is not odd then the systems OSSD’s will remain OFF. Below are examples of ODD parity.

The parity switch (Position 6) is used as a functionality check for the dip switches, making sure no dipswitch has failed. The light curtain counts how many of the 6 switches are in the ON position. This sum must be an odd number. If the number is not odd then the systems OSSD’s will remain OFF. Below are examples of ODD parity.

If the number of switches in the ON position equals an even number then parity switch (Position 6) must be in the ON position. If the number of switches in the ON position equals an odd number then parity switch (position 6) must be in the OFF position. Having set the switches in this way, if any switch subsequently fails, either on or off, the parity will go to an even number and the fault will be detected.