Smartscan Safety Light Curtain T4HD Series: Principle of Operation

Principle of Operation

The Smartscan sensing unit consists of a transmitter and a receiver column that face each other across an area to be safeguarded. The transmitter (TX) contains a row of infrared, light emitting diodes that sequentially transmit parallel beams of energy to corresponding receiving diodes in the receiver(RX) column. When the control/monitoring unit detects an obstruction in the optical path of one, or more of the beams that form the sensing field, the output signal switching devices (OSSD’s) will turn-OFF immediately.

The Smartscan sensing unit consists of a transmitter and a receiver column that face each other across an area to be safeguarded. The transmitter (TX) contains a row of infrared, light emitting diodes that sequentially transmit parallel beams of energy to corresponding receiving diodes in the receiver(RX) column. When the control/monitoring unit detects an obstruction in the optical path of one, or more of the beams that form the sensing field, the output signal switching devices (OSSD’s) will turn-OFF immediately.

Status Indicators

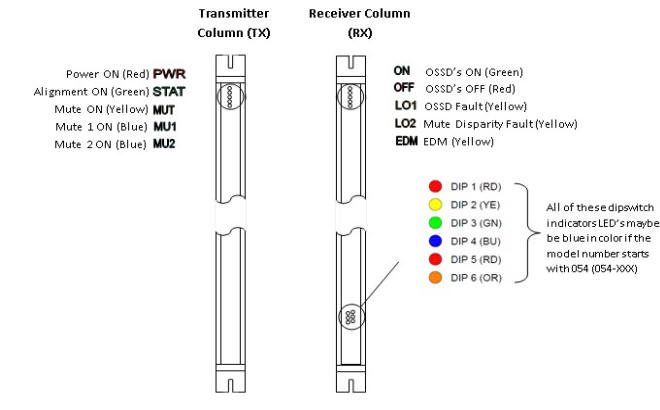

Transmitter Indicators

Top of transmitter column

Power (PWR): Indicates that the transmitter column has power. LED ON

Status (STAT): Indicates that the system is aligned. LED ON

Mute (MUT): Indicates that the light curtain is in the “MUTED” state. LED turns ON.

Mute 1 (MUT1): Indicates that the light curtain has received external mute signal 1 (ON)

Mute 2 (MUT2): Indicates that the light curtain has received external mute signal 2 (ON)

Receiver Indicators

Top of receiver column

OSSD’s ON (ON): Indicate that the safety outputs are energized (ON). LED ON

OSSD’s OFF (OFF): Indicates that the safety outputs are de-energized (OFF) LED ON.

OSSD Fault: (LO1) OSSD fault detected LED ON.

Mute Disparity(LO2): Mute Disparity fault detected. LED ON

External Device Monitoring (EDM): Indicates that the EDM circuit is complete. LED ON

Bottom of receiver column

Dip switches (1- 6): Indicate when dip switches are in the on position. LED ON.

Dipswitch 1 = Red LED

Dipswitch 2 = Yellow LED

Dipswitch 3 = Green LED

Dipswitch 4 = Blue LED

Dipswitch 5 = Red LED

Dipswitch 6 = Orange LED

Transmitter Indicators

Top of transmitter column

Power (PWR): Indicates that the transmitter column has power. LED ON

Status (STAT): Indicates that the system is aligned. LED ON

Mute (MUT): Indicates that the light curtain is in the “MUTED” state. LED turns ON.

Mute 1 (MUT1): Indicates that the light curtain has received external mute signal 1 (ON)

Mute 2 (MUT2): Indicates that the light curtain has received external mute signal 2 (ON)

Receiver Indicators

Top of receiver column

OSSD’s ON (ON): Indicate that the safety outputs are energized (ON). LED ON

OSSD’s OFF (OFF): Indicates that the safety outputs are de-energized (OFF) LED ON.

OSSD Fault: (LO1) OSSD fault detected LED ON.

Mute Disparity(LO2): Mute Disparity fault detected. LED ON

External Device Monitoring (EDM): Indicates that the EDM circuit is complete. LED ON

Bottom of receiver column

Dip switches (1- 6): Indicate when dip switches are in the on position. LED ON.

Dipswitch 1 = Red LED

Dipswitch 2 = Yellow LED

Dipswitch 3 = Green LED

Dipswitch 4 = Blue LED

Dipswitch 5 = Red LED

Dipswitch 6 = Orange LED

Modes of Operation

Automatic Reset: After initial “Power Up” the light curtains OSSD’s become active (OSSD’s are “ON”). If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the light curtain automatically reactivates itself.

(OSSD’s turn “ON” )

Manual reset(Latched): After initial “Power Up” the light curtains OSSD’s remain “OFF” until a start signal is received. Once a Start signal is received the OSSD’s turn “ON”. If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the OSSD’s will remain “OFF” until a reset signal is received, upon which time the OSSD’s will turn “ON”.

Restart Interlock: After initial “Power Up” the light curtains OSSD’s become active (OSSD’s turn “ON”). If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the OSSD’s will remain “OFF” until a reset signal is applied.

Automatic Reset: After initial “Power Up” the light curtains OSSD’s become active (OSSD’s are “ON”). If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the light curtain automatically reactivates itself.

(OSSD’s turn “ON” )

Manual reset(Latched): After initial “Power Up” the light curtains OSSD’s remain “OFF” until a start signal is received. Once a Start signal is received the OSSD’s turn “ON”. If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the OSSD’s will remain “OFF” until a reset signal is received, upon which time the OSSD’s will turn “ON”.

Restart Interlock: After initial “Power Up” the light curtains OSSD’s become active (OSSD’s turn “ON”). If the light curtains sensing unit is blocked the OSSD’s turn “OFF”. Once the obstruction has been removed from the sensing unit the OSSD’s will remain “OFF” until a reset signal is applied.

Other Functions

Muting: In the muted mode the light curtains switching devices (OSSD’s) do not respond to actuation of the sensing unit. In other words, the light curtain does not send a shut down signal when one or more of the infrared beams are obstructed.

Floating Beam Blanking: Floating beam blanking allows the user to create a larger unprotected opening in the light curtain safe guarding barrier. The name floating beam blanking originated due to the fact that the disabled beam(s) are not fixed at specific location. The light curtain will allow a specified number of beams (Maximum of 3 adjacent beams) to be blocked without it sending a stop signal to the safe guarded machine.

Fixed Beam Blanking: Fixed beam blanking allows the user to deselect a fixed area of beams in the light curtain's sensing field. This is typically used when stationary objects, fixtures, tables, etc are permanently obstructing a portion of the sensing field. The remaining unobstructed area of the light curtains sensing field remains active and if something obstructs the active sensing a stop signal is sent to the safe guarded machine.

External Device Monitoring: External Device Monitoring(EDM) is a means of detecting faults in equipment external to the light curtain that is involved in achieving the machine stop condition. For instance, if external relays are used it may be necessary to ensure the relays respond each time the light curtain is interrupted.

Muting: In the muted mode the light curtains switching devices (OSSD’s) do not respond to actuation of the sensing unit. In other words, the light curtain does not send a shut down signal when one or more of the infrared beams are obstructed.

Floating Beam Blanking: Floating beam blanking allows the user to create a larger unprotected opening in the light curtain safe guarding barrier. The name floating beam blanking originated due to the fact that the disabled beam(s) are not fixed at specific location. The light curtain will allow a specified number of beams (Maximum of 3 adjacent beams) to be blocked without it sending a stop signal to the safe guarded machine.

Fixed Beam Blanking: Fixed beam blanking allows the user to deselect a fixed area of beams in the light curtain's sensing field. This is typically used when stationary objects, fixtures, tables, etc are permanently obstructing a portion of the sensing field. The remaining unobstructed area of the light curtains sensing field remains active and if something obstructs the active sensing a stop signal is sent to the safe guarded machine.

External Device Monitoring: External Device Monitoring(EDM) is a means of detecting faults in equipment external to the light curtain that is involved in achieving the machine stop condition. For instance, if external relays are used it may be necessary to ensure the relays respond each time the light curtain is interrupted.